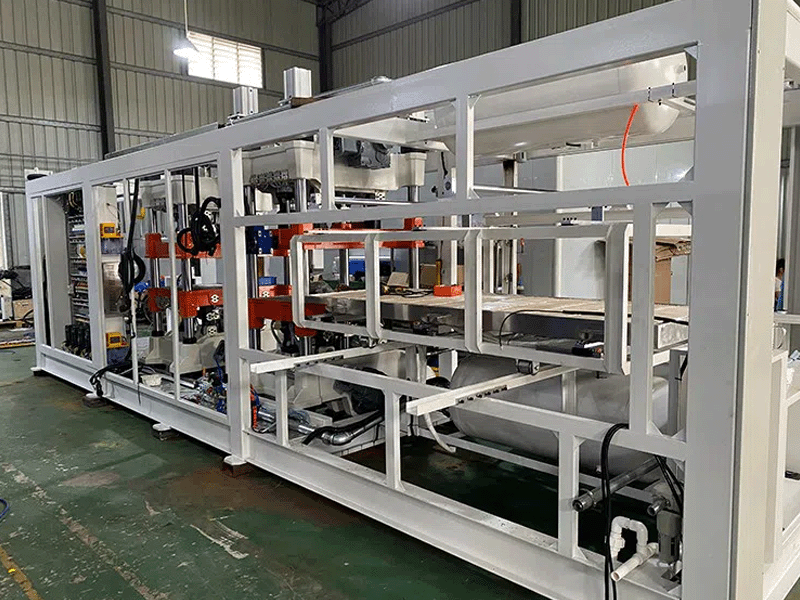

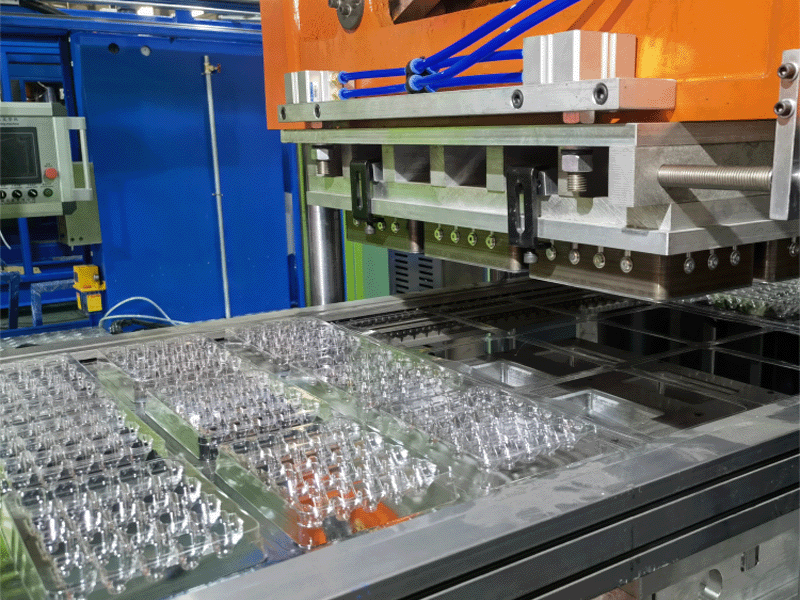

1. The D&M60 series Four station automatic plastic thermoforming machine is a new model that has been continuously optimized and designed according to the new requirements of plastic product processing.

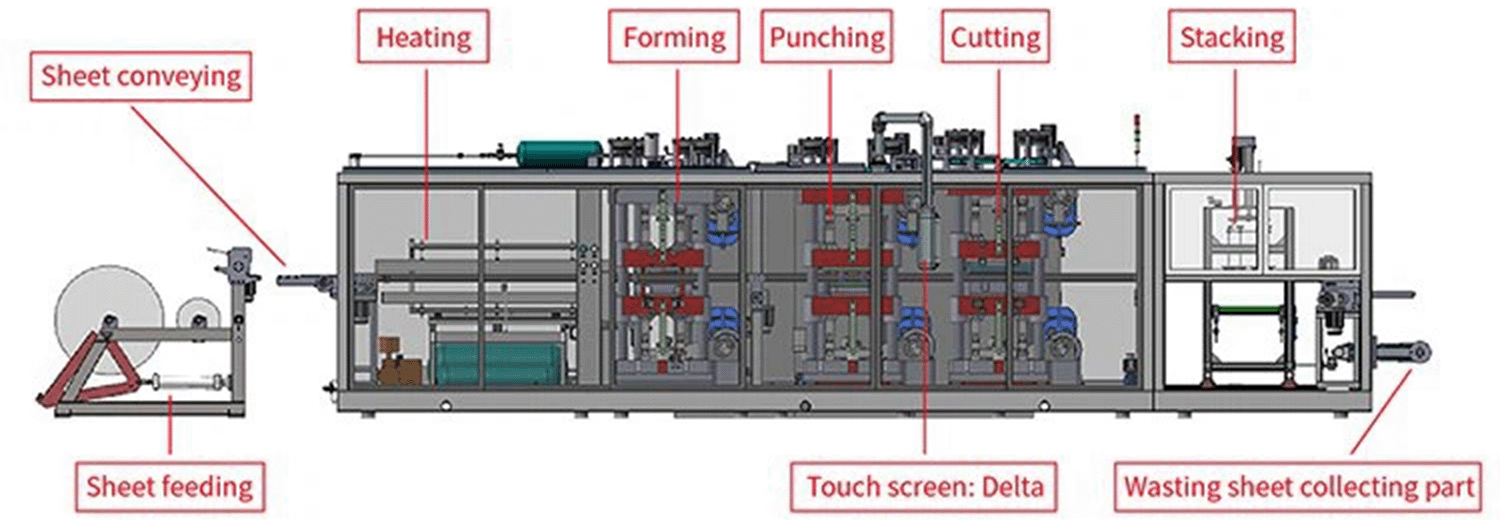

2. It has a wide range of uses, stable motion, low noise, reliable work, high finished product qualification rate, wide application of sheet materials, forming, trimming, finished product output, and waste rewinding are all fully automated and continuous production.

3. Four station automatic plastic thermoforming machines can greatly save manpower and space, reduce costs, and improve economic benefits.

Contact Us

|

Model |

DM-60 |

|

Name |

Four Stations Automatic Plastic Thermoforming Machine |

|

Applicable raw materials |

PP, PS, PET, PVC, OPS, degradable materials, PLA, etc. |

|

Forming method |

vacuum and pressure forming |

|

The maximum forming mold area |

Width 780×length 600mm |

|

The minimum molding die area |

420×300mm |

|

Applicable sheet thickness |

0.15-2.0mm |

|

Maximum punching area |

780×600mm |

|

Cutting knife line |

8M knife line |

|

Maximum opening and closing stroke of forming mold |

150mm |

|

Molded product height |

130mm |

|

Stacking mechanism |

Hanging point stacking |

|

Power access |

380V/50HZ (three-phase five-wire) |

|

Total Weight |

13,000kg |

|

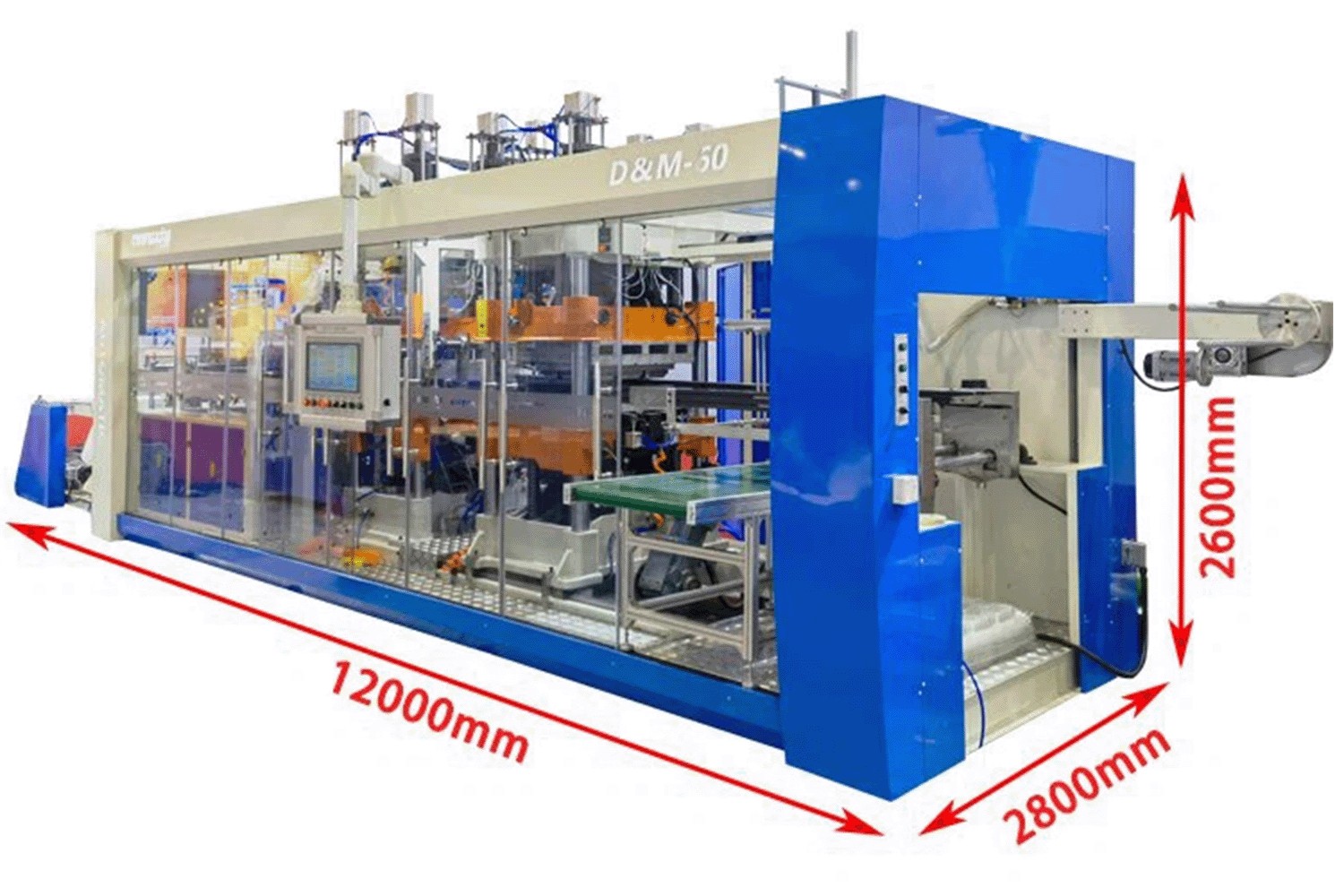

Dimension |

L11.8m×W2.4m×H2.6m |

|

|

Name |

Brand |

|

Control System |

Control System |

Beckhoff System |

|

Programmable Controller (PLC) |

Beckhoff System |

|

|

Touch display |

15-inch color touch monitor |

|

|

Pull tab servo system |

Pull tab servo system |

Switzerland ABB |

|

Pull tab gearbox |

High-precision planetary reducer |

|

|

Chain guide |

Aerospace aluminum alloy surface hard oxygen treatment |

|

|

Pull tab chain |

Taiwan KMC (double-row guide chain) |

|

|

Rail (beam) cooling system |

The whole beam is cooled by water (circulating water) |

|

|

Rail adjustment |

The guide rail is electrically adjusted and can be adjusted in one direction |

|

|

Drive System |

Cycles |

40 times/minute |

|

Forming Servo System |

Switzerland ABB |

|

|

Punching and cutting servo system |

Switzerland ABB |

|

|

Stack Servo System |

Switzerland ABB |

|

|

Station structure |

Cam structure |

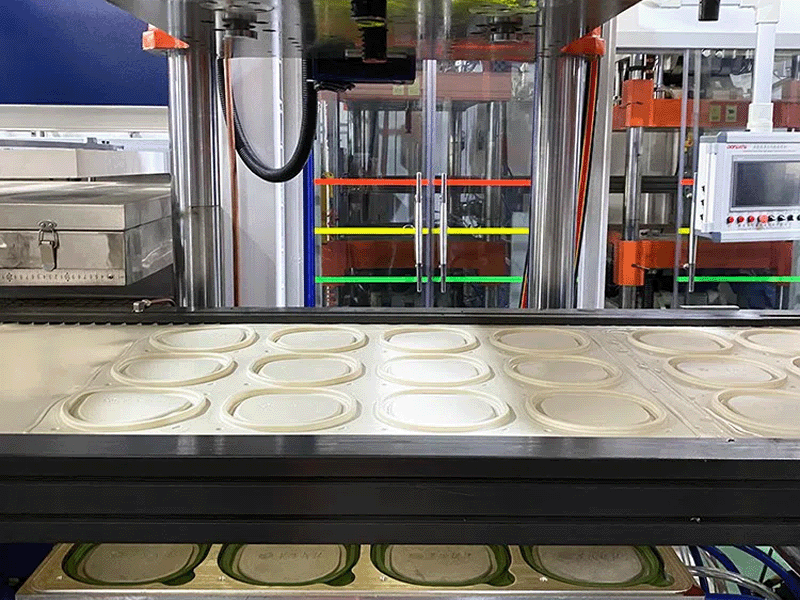

This Four Stations Automatic PVC thermoforming machine can be widely used in the production and production of all kinds of disposable plastic light containers and plastic products. Such as: instant noodle bowl, fruit box, fast food box, pastry box, electronic tray, hardware, daily necessities packaging box, etc.

Fast to understand the DM60, if you want to know the answers, please write to [email protected] for the full answers.

Cup over

Disposable fast food box

Jelly cup

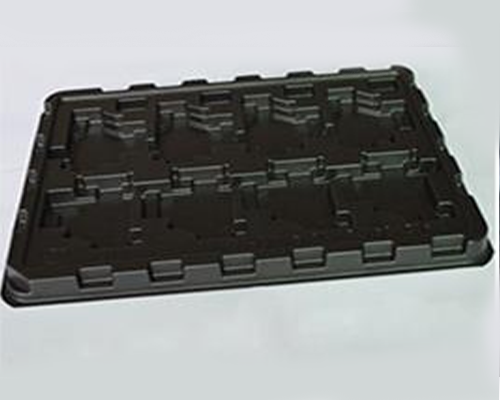

Electronic tray

Electrical plastic packaging

Fresh tray

Fruit box

Disposable food box

Moon cake

Copyright 2019 All Right Reserved.