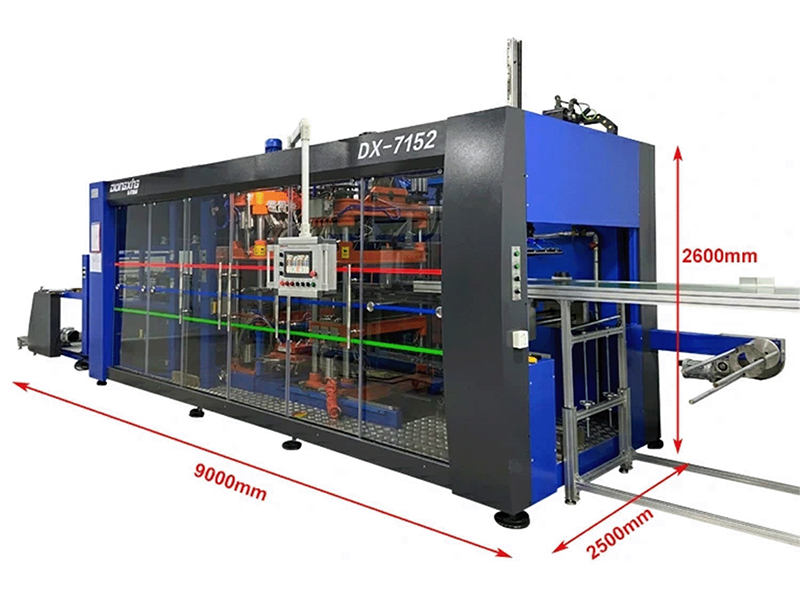

The main body of the Three Stations Fully Automatic Plastic Pvc Fruit Box Vacuum Forming Machine: Fruit Box Vacuum Forming Machine is formed by splicing and welding steel structure profiles such as square pass and channel steel, which is used for assembling heating, mold table forming, mold table punching, and auxiliary devices. The overall steel structure frame is guided by the, and all the parts involved are fully in line with: high-quality selection of materials, blank production methods, machining, heat treatment, parts assembly, machine operation, machine maintenance, and other technological foundations, To ensure that the movable device that transmits and transforms motion and force has sufficient strength and rigidity. All metal surfaces are treated with anti-rust and the bottom layer is sprayed with anti-rust paint; common parts and standard parts are used in the structure, which is convenient for later maintenance and replacement of all parts.

1. Automatic Plastic Fruit Box Vacuum Forming Machine uses a microcomputer touch screen man-machine interface control system, the operation is intuitive and easy to operate, convenient, and easy maintenance.

2. High speed, low noise, durable, and easy to maintain; 3s/time.

3. Introduce an absolute-servo control system, coupled with an advanced automation system for process any PP PS marking, OPS marking, PE, PVC, APET and CPET, DW3, THE, the high-speed injection molding machines are impeccable.

4. The mold replacement bodies with new design ensure extremely shorter mold the changing times, simple mold replacement system designed in accordance with established human efficiency optimization, as well as steel cutting and stacking devices to ensuring maximum production time.

|

Model |

HG-DX7152 |

|

Machine name |

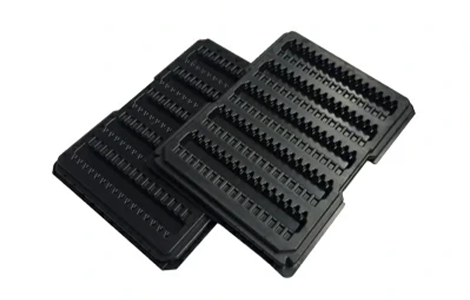

Pvc Fruit Box Vacuum Forming Machine |

|

Applicable raw materials |

PP, PS, PET, PVC, OPS, degradable materials, PLA, etc. |

|

Forming method |

Positive and negative pressure forming |

|

The maximum forming mold area |

Width 710×Length 850mm |

|

Minimum molding die area |

420×300mm |

|

Maximum sheet width |

750mm |

|

Applicable sheet thickness |

0.15-2.0mm |

|

Maximum punching area |

710×520mm |

|

Cutting line |

6m knife line |

|

Maximum opening and closing stroke of forming mold |

120mm |

|

Molded product height |

80mm |

|

Mold height |

150mm |

|

Stacking mechanism |

Hanging point stacking |

|

Rated power of the whole machine |

80kw |

|

Power consumption |

25-50kw |

|

Power access |

380V/50HZ (three-phase five-wire) |

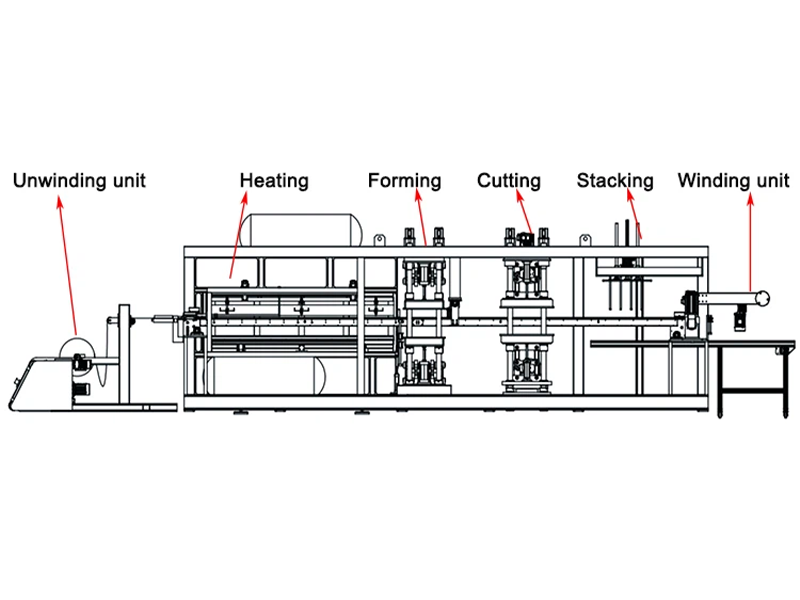

Forming mold

Cutting mold

Mechanical stacking station

Unwinding unit

Winding unit

Transport station

Copyright 2019 All Right Reserved.